Construction industry trends to look out for in 2020

February 28, 2020Going on a Date? Here are some Top First Date Ideas

February 29, 2020There are many different options available when it comes to coating products to provide a protective or decorative finish. Paint, powder coating or electroplating processes are all in common use.

An increasingly popular technique is the use of thermal plasma spray. As the name implies, this involves the use of heat to soften particles so that they form an even coating when they hit the surface to be treated. The technique is used on products for use in a wide range of industries from the automotive sector to aerospace, agriculture and even medical and food production equipment.

How does it work?

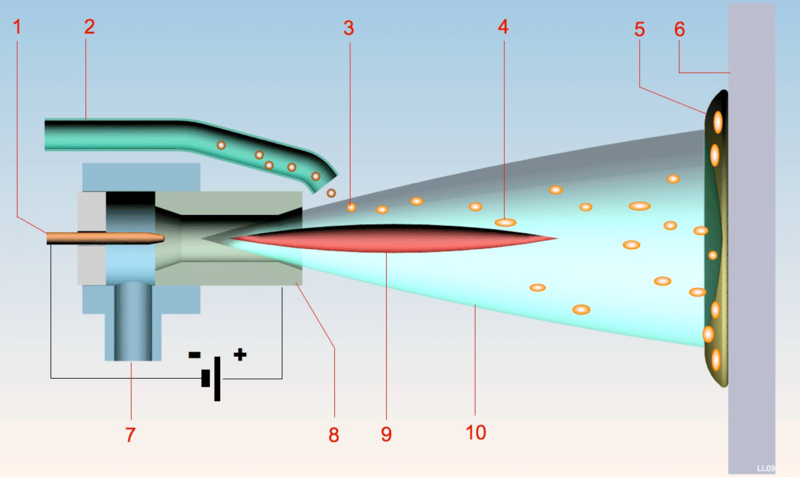

The application of the coating involves the use of a hot plasma gun. The coating material is fed into this in the form of a powder. This is melted in the gun using a plasma flame and then sprayed onto the surface to be treated.

A number of materials with high melting points can be applied using a thermal plasma spray, and the process can be used to protect a whole range of materials including glass, metal, ceramics and even plastics. The thickness of the coating applied can be very accurately controlled down to a few microns. This controllability plus the choice of coatings and substrates available means this is a supremely versatile process.

Where is it used?

Because of its versatility, plasma coating can be found on many different products across a wide range of industry sectors. Depending on the material being applied, the coating can provide not only protection, wear resistance and an easy-to-clean surface, but it may also offer insulation properties as well as heat resistance.

Thermal coatings can be found on industrial machinery and hospital equipment, but also on domestic items such as household appliances and kitchen utensils. The non-stick coating on your frying pan was quite probably applied using a hot plasma spraying technique. In healthcare environments, coatings can be used to provide an antibacterial protection.

It is no surprise that plasma coatings can be found employed in some pretty harsh environments. These include gas turbine blades and other turbine components, mining equipment and drilling tools for the oil and gas industries. It can also be found coating the impellers and other components of pumps to ensure a long life and a smooth flow.